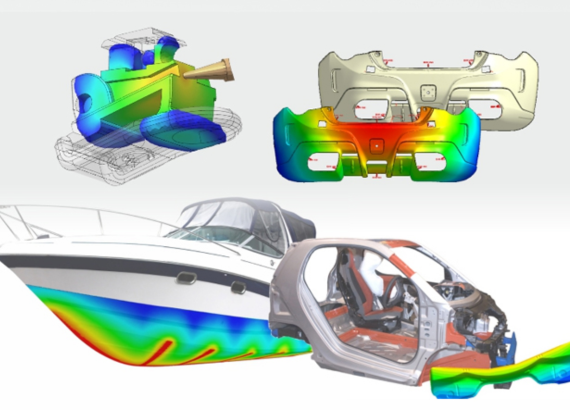

Moldex3D is widely used across various industries, including automotive, consumer electronics, medical devices, and packaging. Its advanced features help users better understand the intricacies of the injection molding process, leading to the creation of high-quality parts with fewer errors, faster production times, and lower costs.