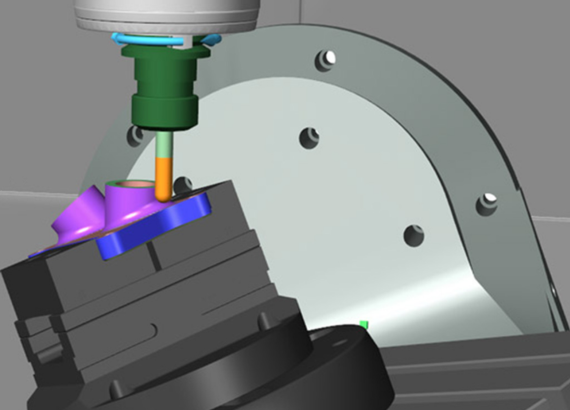

In addition, NCSIMUL Optitool optimizes machining processes by reducing air-cutting and improving feed rates. This module helps users develop better cutting strategies, contributing to enhanced machining efficiency and extended tool life. Furthermore, NCSIMUL 4CAM provides unparalleled flexibility on the shop floor. It allows users to make adjustments to the target machine without needing to reprogram the CAM, streamlining operations and saving valuable time.