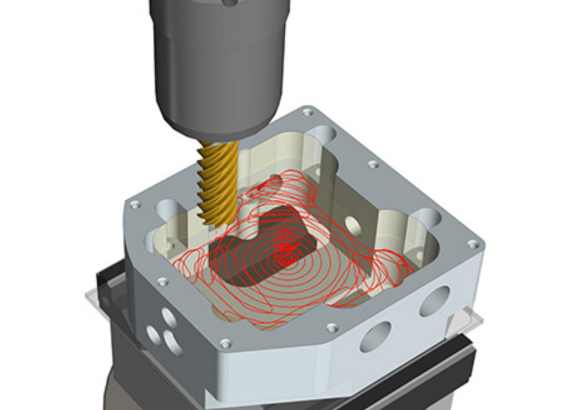

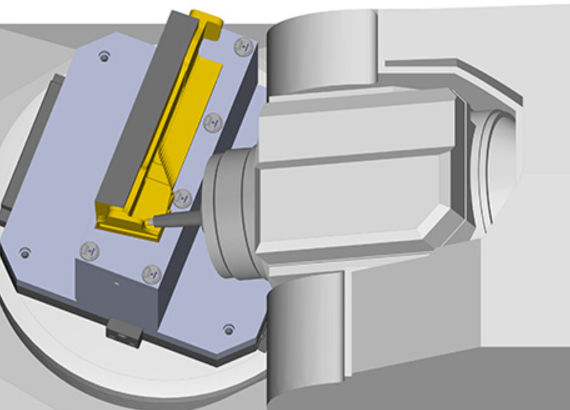

The AI-powered system intelligently drives the machine's movements, ensuring optimal tool paths and reducing cycle times. Whether you’re handling complex multi-axis machining or simple milling tasks, ESPRIT EDGE adapts to meet your unique needs, offering maximum efficiency and reliability in your production processes. By leveraging Digital Twin Tachnology, ESPRIT EDGE creates a virtual model of your manufacturing processes, allowing for precise simulation, analysis, and optimization before physical machining begins. This ensures a higher level of accuracy, minimizes errors, and maximizes the overall efficiency of your CNC operations.