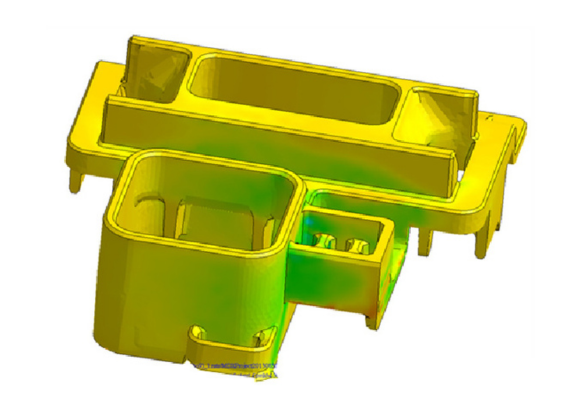

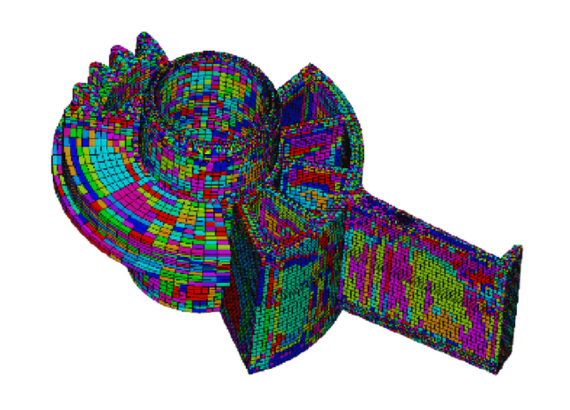

The Solution Addons suite offers advanced tools designed to optimize the design and analysis of fiber-reinforced plastic parts. These powerful addons enable users to visualize fiber orientation and calculate process-induced anisotropic thermo-mechanical properties for both long and short fiber-reinforced plastics. By simulating these properties, users can predict warpage distribution and assess the strength of parts, ensuring that the final products meet structural performance requirements.The Micromechanics Interface integrates with software like Digimat and Converse, allowing users to output detailed material properties for nonlinear multi-scale material modeling before conducting further Finite Element Analysis (FEA).

Whether you're looking to enhance productivity, improve efficiency, or stay ahead of technological advancements, we've got you covered.

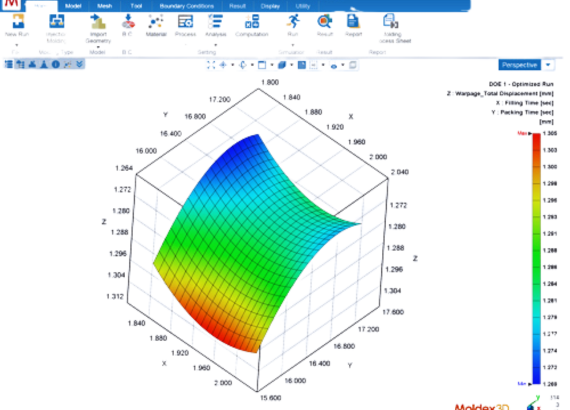

helps users evaluate the optimal process conditions, such as packing time, cooling time, or mold temperature. Moldex3D Expert creates analysis variations and provides graphical summaries automatically.

provides a series of FEA Interface modules integrated with industrial leading structural software, including ABAQUS, Ansys, LS-DYNA, Marc, Nastran, and Radioss.Users can export Fiber and Stress analysis results to calculate further structural performance.

calculates viscosity and elasticity variations of plastic materials under different temperature conditions. Users can evaluate the effects on molecular orientation, residual stress, warpage, and optical properties.

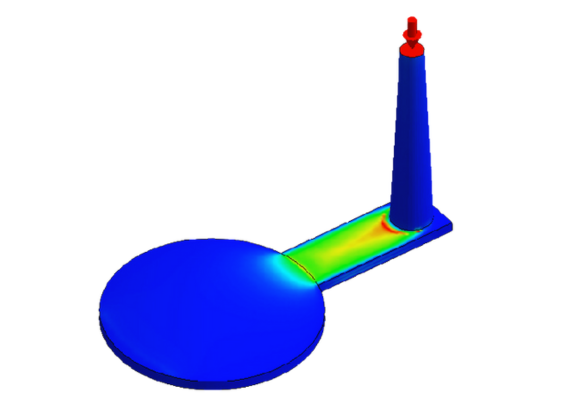

simulates the compression molding process in which the polymer is squeezed into a preheated mold cavity. Moldex3D helps users check potential defects resulted from heat and pressure, decide appropriate materials, and optimize process conditions.