Moldex3D AEP Package offers all users, from product and mold designers to advanced CAE experts, the ability to obtain the details of all types of designs, from thin-wall molded parts to complex models with fine features.

AEP Solution Package provides 3D Coolant CFD to fulfill RHCM and Conformal Cooling requirements to bring more benefits and value to users. BLM (Boundary Layer Mesh) module with Non-Matching mesh technology is also added into preprocessing interface to facilitate the part and mold creation and auto meshing technology enable users to work in CAD with no need for advanced CAD knowledge.l

In addition, the diversity and robustness of elements ensure the fidelity of solutions. Combining the advantages of 2.5D and 3D modeling, Moldex3D AEP Package ensures the accurate and efficient performance for every design. Users are able to obtain product insights and properties, and further to optimize processes before physical parts are built. Moldex3D AEP Package helps companies to design products with confidence, reduce development costs, and shorten time to market.

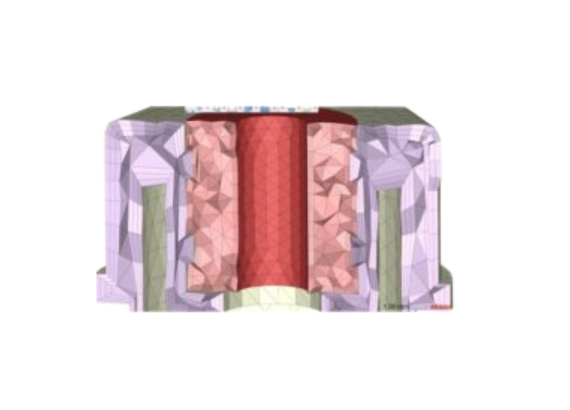

Moldex3D AEP Package provides a variety of meshing tools to build 2.5 D and 3D models that are precise and efficient. For conventional injection molded parts with big surface area and shell-like characteristics, Moldex3D AEP Package provides meshing tools to build 2.5D mid-plane (shell) models that are fast and robust to solve. The 3D eDesign meshing provides an automatic workflow for users to build their parts with ease. Auto wizards guide you through steps of creating melt deliver systems, coolant channels and moldbases, with automated error detection. Additionally, the robustness of various solid elements allows users to observe the detailed information of particular areas, including designed fine features and flow behavior around gates and corners. The pre-processors amplify the power of injection molding simulation, simplify the model creation and enable plastics engineers to innovate efficiently.

Moldex3D AEP Package can simulate complex 2.5D models in minutes. In addition, its powerful 3D solvers tackle complex injection-molded parts with confidence and efficiency. Designers are able to obtain in-depth knowledge and detect potential defects from comprehensive analyses. The Material Database and Process Wizard assist users to easily iterate on design changes and optimize their processes in early stages.

Moldex3D AEP Package tackles the complex injection molding process with high fidelity simulation results. Its powerful meshing algorithms allow fast calculations of conventional shell-like parts and efficient parallel computing of any complex 3D geometry. Furthermore, its flexible meshing capabilities enable versatile extension to advanced molding process for insightful process innovation. Its unique high performance parallel computing makes the true 3D simulations fast and efficient.

Post-processing tools enable users to demonstrate molding process and product properties with real-time contours, graphs and animation. From the automatic report generator, you can benefit on quick reports and efficient communication. Moldex3D brings you confidence in your design and helps you in successful decision making.